How to Make a DIY Patchwork Jacket Using Iron Patches

When it comes to making a DIY patchwork jacket with iron patches, oh, failure is everywhere. Like glue stains, you didn’t notice until it dried.

When it comes to making a DIY patchwork jacket with iron patches, oh, failure is everywhere. Like glue stains, you didn’t notice until it dried.

I used to think the Step-by-Step Guide to Creating a Patch-Filled Denim Vest was just, well, instructions. Like IKEA furniture manuals, only with more colour and less tiny hex keys.

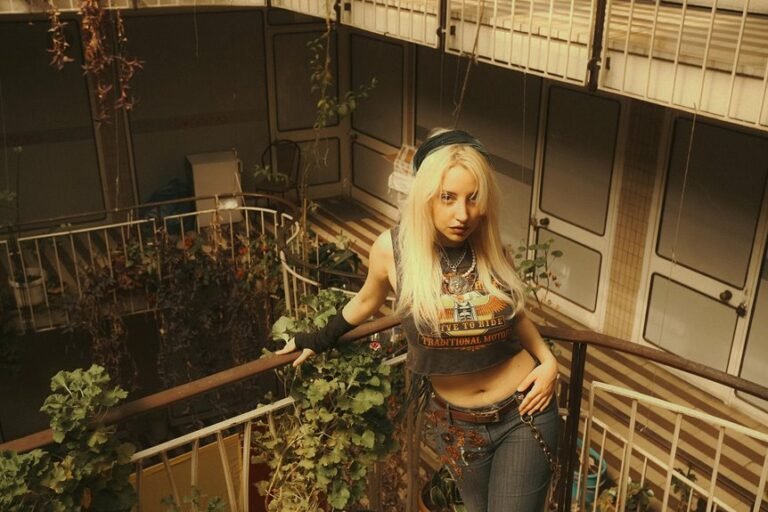

Here’s the thing: people love custom patches. They’re like tattoos for fabric, little emblems of personality, humour, memory.

Most of us think we know how to slap a custom embroidered patch on. You line it up, measure from edge to edge, maybe squint a little, and boom, you’re done. Except, wait.

Funny thing about patchwork tote bags. People think they’re simple. Stitch some fabric squares together, maybe an old pair of jeans cut up, toss on a handle, done.

Applying iron patches is not rocket science, but it’s also not as simple as tossing an iron on top and hoping for the best.

The custom patches peeling off like cheap stickers in the first wash. The shame of seeing your “custom design” look nothing like you imagined.

You’re staring at custom patches, thinking “oh wow, that red looks sharp” or “nice logo work there.” And then, two weeks later, it’s peeling, threads fraying like a cheap sweater you bought.

Often the smallest, most overlooked things, those tiny threads of consideration, are the ones that can totally make or break your bulk custom patch order.

Explore the pros and cons of iron-on, Velcro, and sew-on patches to find the perfect backing option for your needs and discover which one reigns supreme!

No products in the cart.