How to Make a DIY Patchwork Jacket Using Iron Patches

Failure is strange. Sometimes it crushes you, other times it teaches you faster than any YouTube tutorial ever could. When it comes to making a DIY patchwork jacket with iron patches, oh, failure is everywhere. Like glue stains, you didn’t notice until it dried.

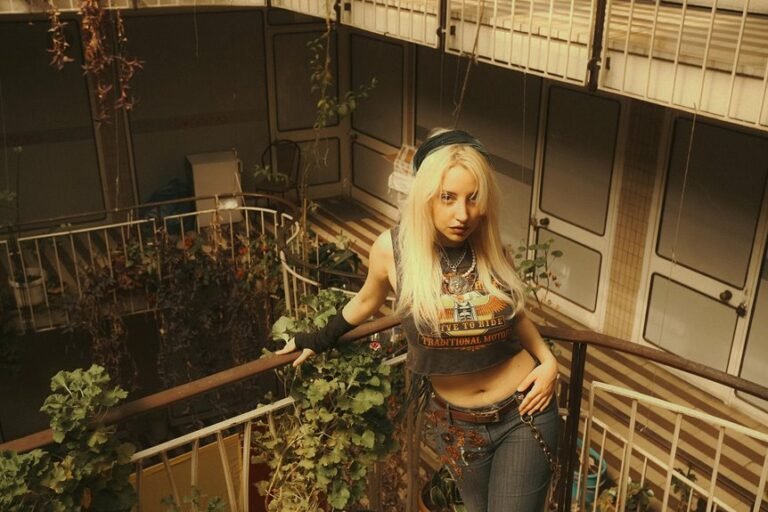

I’ve seen it myself. That burst of excitement: a pile of shiny custom embroidered patches, an old denim jacket, an iron heating up like you’re about to start a revolution. And then… disappointment. Corners curling, threads fraying, the design looking less like runway couture and more like something from a rushed school project.

But here’s the twist: these “mistakes” aren’t just random. They’re patterns, repeated by people in Karachi and Kansas, in 2025 or 1985. Understand them, and suddenly you’re not fumbling, you’re learning the shortcuts others didn’t.

So, let’s tear it apart (gently). The common failure points. The silent killers of your patchwork dreams. And of course, how to dodge them like a pro.

Failure Point: Pretending All Fabrics Are Created Equal

This is the first blunder. You think any jacket, any material, will accept your patches like a blank page welcomes ink. Not true. Cotton? Easy-going, a hugger. Denim? Stubborn but loyal. Polyester? Slippery, like trying to glue something onto Teflon.

Why does this happen? Simple. Packaging lies. It says “iron-on,” no warnings, no fine print about synthetics. And you, full of caffeine and ambition, trust it.

The cost? Oh, it’s brutal. The patch lifts after two washes, usually right before you want to show it off. Wasted time, wasted glue, wasted ego. You start thinking DIY is just for those crafty TikTok geniuses.

What to do instead: know your fabric. Read the label, touch it, stretch it. If it feels slick, you’ll need extra reinforcement (stitching, stronger adhesives). For leather or canvas, yeah, that bomber jacket you thrifted, you’ll need a heavier plan.

Failure Point: Skipping the Boring Prep Work

Here’s the thing. Everyone wants to jump straight into the “fun part.” Positioning iron-on patches, playing designer. But skipping prep is like trying to fry eggs in a dirty pan, you’ll end up with residue.

People don’t wash the jacket first. They don’t iron it flat. They don’t clear away lint or oils. Invisible enemies, but deadly.

Result? Adhesives don’t stick. Corners lift. Your masterpiece looks… tired. Worse, sometimes the patch is ruined forever. And nobody tells you how much custom iron patches cost these days, especially those trending limited-edition anime ones.

Solution? Prep like a surgeon. Wash, dry, skip the softener (seriously, it leaves residue that laughs at glue). Iron flat before laying anything down. And, this one I swear by, take a photo of your layout so you don’t “forget” the genius arrangement you made at 2 a.m.

Failure Point: Misunderstanding Heat and Pressure

The iron, the supposed hero, is also the saboteur. Too hot and the fabric scorches, you smell it before you see it. Too cold and nothing bonds, so the patch becomes decorative confetti.

Most of us assume “crank it up” is the answer. It isn’t. Adhesives are like chocolate: melt them gently, or you burn the whole thing.

The hidden cost? A jacket ruined in seconds. Or worse, a half-stuck custom patch that pretends it’s secure but betrays you after the first rainy commute. Then you’re ironing again, again, weakening the bond further. A vicious loop.

Fix it with balance. Medium heat. Press, don’t slide. Use a cotton cloth as a barrier, it’s like sunscreen for your fabric. Hold steady 20–30 seconds. Flip, do the back side too if it’s thick denim. This is patience disguised as technique.

Failure Point: The Chaos of Overcrowding

This one’s psychological. You’ve got twenty patches and one jacket. Your brain says: use them all, NOW. But the result is chaos. No focal point, no breathing room, like scrolling Twitter during an election year, overwhelming noise with no clarity.

Why? Because creativity, unchecked, spills everywhere. And nobody ever told you restraint was also a skill.

The cost? Your jacket looks less like fashion and more like a scrapbook exploded on it. Worse, overlapping embroidered custom patches don’t bond well, so you end up with peeling edges. Ironing over lumps never works.

The fix: space things out. Think symmetry, or deliberate asymmetry, like streetwear brands do. Highlight one big statement iron patch. Sometimes less is louder. Remember Virgil Abloh’s “10% rule”? Minimal change, maximum impact. Apply that here.

Failure Point: Believing ‘Iron-On’ Means Forever

Here’s the cruelest joke. People think “iron-on” means permanent. It doesn’t. It means “temporary convenience.” Patches are vulnerable, especially around the edges. Movement, washing, time, they all pry at the weak spots.

Why is this skipped? Because reinforcement feels extra. Optional. And optional is easy to ignore.

The price? Endless repair cycles. That sense of defeat when your favourite patch starts dangling mid-conversation. Or worse, it vanishes in a washing machine abyss.

How to fix? Reinforce, always. A thin bead of fabric glue around the edges, invisible insurance. For high-stress spots (sleeves, elbows), stitch. Doesn’t matter if it’s messy, messy stitches scream authenticity. Think of punk jackets from the ‘80s, glue plus thread kept them alive through mosh pits and chaos.

Conclusion: Failures Aren’t Fatal, They’re Clues

Here’s the truth: every failed jacket is just a lesson disguised as disappointment. The fabric that rejected glue? It taught you to pay attention. The burnt custom iron-on patch? A reminder that patience is underrated. The chaotic design? Proof that restraint is as powerful as creativity.

DIY isn’t about perfection. It’s about persistence. It’s about treating mistakes as tuition fees for mastery.

So next time you line up patches, pause. Ask yourself: am I repeating a failure, or adapting from it? That choice, that pause, is the difference between another half-hearted attempt and a jacket that people stop you in the street to ask about.

Failure is inevitable, yes. But failure, handled right, is the fuel. So, what will you do with yours?